The first revolvers were built for the popular .357 Magnum cartridge.

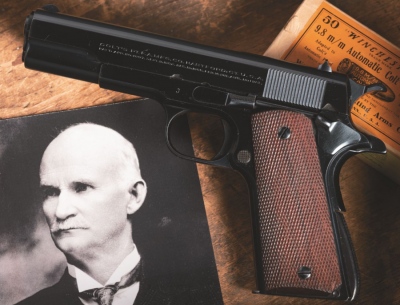

Daniel Baird Wesson II, more widely known as Dan Wesson, was a man whose future was predetermined before he was even born in 1916. His great-grandfather, Daniel Wesson, gave the second part of the name to "Smith & Wesson," and gunsmithing, perhaps even more than entrepreneurship, has flowed in the veins of his descendants ever since.

A trained engineer with several patents to his credit, he worked for his ancestors' company for 30 years. He was responsible for completing developments such as the first .357 and .44 Magnum and led the company's dominance in the revolver market. Since 1948, he had founded his own small business (DW Inc., specializing in the production of machining equipment), in parallel with the family activities.

The split

The late 1960s found the family struggling to maintain ownership of "S&W" against aggressive takeovers. When the family company passed into the ownership of the multinational Bangor Punta, Dan resigned from management. At 50 years old, he felt too young to retire.

In 1968, he started D.B. Wesson Arms. With two gunsmiths who followed him from the old factory as staff, he started making what he knew best: quality revolvers.

The first Model 11 (notably, the most popular "S&W" is the Model 10) came onto the market in 1970. The improved 12, 13, 14, and 15 followed.

Engineering progress

The basic design of the "Smith & Wesson" dates back to the late 19th century. Free from the "family legacy," he brought a new method of construction to the forefront.

Dan Wesson revolvers used a modern, more durable mechanism. The biggest innovation was in the way the barrel was mounted on the frame. The barrels feature two threads—one on each end. One side screws onto the frame and locks at the correct distance for the necessary "gap." An outer sleeve is then fitted around it. It contains the ejector shroud and the base for the sight pin. A ring tightens the sleeve onto the second thread (towards the muzzle of the barrel), thus joining the two parts. A special wrench allows the owner to perform this task at will.

Dan Wesson offered barrels between 2.5 (6cm) and 10 (25cm) inches, and very often, the guns were sold in sets with three or four alternatives. Thus, for example, the same frame could be used daily for concealed carry and changed in a few minutes for target shooting or hunting. The sights were also easily changed with the help of a wrench and adapted to different requirements.

At the other end of the frame, Dan replaced the traditional grip frame with an elongated frame. Thus, the grips were no longer bound by the dimensions of the mechanism. There were two basic sizes of wooden grips that screwed onto the frame: one was smaller for concealment, while the other was more suitable for target use. For some time, the factory supplied unshaped pieces of wood so users could carve the ideal shape for their own hands.

The cylinder lock-up was improved with an extra latch on the front axis and a bulky button.

This level of modularity was unheard of at a time when the big names (Colt and S&W) offered few options, and any customization required expensive conversions by gunsmiths.

Excessive power

The first revolvers were built for the popular .357 Magnum cartridge. Soon, the design shrank to accept smaller calibers (.22 Long, .32 HR mag) and grew for the .44 Magnum.

The ability to change barrels attracted the interest of Metallic Silhouette shooters. In this sport, participants are required to hit metal silhouettes of animals (chicken, piglet, turkey, ram) at distances of 50, 100, 150, and 200 meters. The shot only counts as successful if the target is knocked over. Therefore, besides accuracy, power is also required.

Shooters used hand-loaded cartridges with heavier bullets to ensure momentum at long distances. They began ordering barrels up to 15 inches (38cm) in length from DAN WESSON.

The company responded, and soon Daniel Wesson's team developed more durable revolvers for the even more powerful .357, .414, and .445 "Supermagnum" cartridges. These cartridges were elongated versions of the .357, .41, and .44 Magnum that produced higher velocities and increased energy. Although their production ceased around 2000, these guns still hold most of the records in the sport.

Intensive use showed that the high pressures literally melted the metal at the junction of the barrel with the frame, and production soon stopped. The remaining "Dan Wesson" Supermagnum revolvers are now considered rare collector's items.

Troubled course

The death of Daniel Wesson on November 24, 1978, put the company on a trajectory of decline. It ended up in the hands of investors unrelated to the family and went bankrupt in 1990.

His son, Seth Wesson, bought the bankrupt company in 1990. He moved the equipment to new facilities and began producing new guns under the brand name "Wesson Firearms." This status was maintained for six years before the business closed once again.

The patents passed to one or two more corporate entities before CZ-USA acquired them in 2005. Since then, "DAN WESSON" has operated under Czech control and with a different focus.

They now manufacture handcrafted pistols based on the Colt M1911 pattern. They have an excellent reputation for quality that puts them "a step above" mass-produced weapons.

www.bankingnews.gr

A trained engineer with several patents to his credit, he worked for his ancestors' company for 30 years. He was responsible for completing developments such as the first .357 and .44 Magnum and led the company's dominance in the revolver market. Since 1948, he had founded his own small business (DW Inc., specializing in the production of machining equipment), in parallel with the family activities.

The split

The late 1960s found the family struggling to maintain ownership of "S&W" against aggressive takeovers. When the family company passed into the ownership of the multinational Bangor Punta, Dan resigned from management. At 50 years old, he felt too young to retire.

In 1968, he started D.B. Wesson Arms. With two gunsmiths who followed him from the old factory as staff, he started making what he knew best: quality revolvers.

The first Model 11 (notably, the most popular "S&W" is the Model 10) came onto the market in 1970. The improved 12, 13, 14, and 15 followed.

Engineering progress

The basic design of the "Smith & Wesson" dates back to the late 19th century. Free from the "family legacy," he brought a new method of construction to the forefront.

Dan Wesson revolvers used a modern, more durable mechanism. The biggest innovation was in the way the barrel was mounted on the frame. The barrels feature two threads—one on each end. One side screws onto the frame and locks at the correct distance for the necessary "gap." An outer sleeve is then fitted around it. It contains the ejector shroud and the base for the sight pin. A ring tightens the sleeve onto the second thread (towards the muzzle of the barrel), thus joining the two parts. A special wrench allows the owner to perform this task at will.

Dan Wesson offered barrels between 2.5 (6cm) and 10 (25cm) inches, and very often, the guns were sold in sets with three or four alternatives. Thus, for example, the same frame could be used daily for concealed carry and changed in a few minutes for target shooting or hunting. The sights were also easily changed with the help of a wrench and adapted to different requirements.

At the other end of the frame, Dan replaced the traditional grip frame with an elongated frame. Thus, the grips were no longer bound by the dimensions of the mechanism. There were two basic sizes of wooden grips that screwed onto the frame: one was smaller for concealment, while the other was more suitable for target use. For some time, the factory supplied unshaped pieces of wood so users could carve the ideal shape for their own hands.

The cylinder lock-up was improved with an extra latch on the front axis and a bulky button.

This level of modularity was unheard of at a time when the big names (Colt and S&W) offered few options, and any customization required expensive conversions by gunsmiths.

Excessive power

The first revolvers were built for the popular .357 Magnum cartridge. Soon, the design shrank to accept smaller calibers (.22 Long, .32 HR mag) and grew for the .44 Magnum.

The ability to change barrels attracted the interest of Metallic Silhouette shooters. In this sport, participants are required to hit metal silhouettes of animals (chicken, piglet, turkey, ram) at distances of 50, 100, 150, and 200 meters. The shot only counts as successful if the target is knocked over. Therefore, besides accuracy, power is also required.

Shooters used hand-loaded cartridges with heavier bullets to ensure momentum at long distances. They began ordering barrels up to 15 inches (38cm) in length from DAN WESSON.

The company responded, and soon Daniel Wesson's team developed more durable revolvers for the even more powerful .357, .414, and .445 "Supermagnum" cartridges. These cartridges were elongated versions of the .357, .41, and .44 Magnum that produced higher velocities and increased energy. Although their production ceased around 2000, these guns still hold most of the records in the sport.

Intensive use showed that the high pressures literally melted the metal at the junction of the barrel with the frame, and production soon stopped. The remaining "Dan Wesson" Supermagnum revolvers are now considered rare collector's items.

Troubled course

The death of Daniel Wesson on November 24, 1978, put the company on a trajectory of decline. It ended up in the hands of investors unrelated to the family and went bankrupt in 1990.

His son, Seth Wesson, bought the bankrupt company in 1990. He moved the equipment to new facilities and began producing new guns under the brand name "Wesson Firearms." This status was maintained for six years before the business closed once again.

The patents passed to one or two more corporate entities before CZ-USA acquired them in 2005. Since then, "DAN WESSON" has operated under Czech control and with a different focus.

They now manufacture handcrafted pistols based on the Colt M1911 pattern. They have an excellent reputation for quality that puts them "a step above" mass-produced weapons.

www.bankingnews.gr

Σχόλια αναγνωστών